-

History of:

- Resources about:

- More:

- Baby walkers

- Bakehouses

- Bed warmers

- Beer, ale mullers

- Besoms, broom-making

- Box, cabinet, and press beds

- Butter crocks, coolers

- Candle snuffers, tallow

- Clothes horses, airers

- Cooking on a peat fire

- Drying grounds

- Enamel cookware

- Fireplaces

- Irons for frills & ruffles

- Knitting sheaths, belts

- Laundry starch

- Log cabin beds

- Lye and chamber-lye

- Mangles

- Marseilles quilts

- Medieval beds

- Rag rugs

- Rushlights, dips & nips

- Straw mattresses

- Sugar cutters - nips & tongs

- Tablecloths

- Tinderboxes

- Washing bats and beetles

- Washing dollies

- List of all articles

Subscribe to RSS feed or get email updates.

"The German Saucepan" is best for boiling milk in. This is an iron saucepan, glazed with a smooth white enamel, which so expands or contracts with the metal as not to chip or crack ; and is in every respect equal to the ingenious method long practised in Germany, instead of tinning the interior surface. The glaze prevents all tendency to burn. A stewpan made like it is also preferable to a copper pan, since simple washing keeps it sweet and clean....now manufactured at Wolverhampton...

Timbs' Manual of Domestic Economy, London, 1847 (see 1839 in timeline)

Poison In The Saucepan. A correspondent...warns the public against the use of iron saucepans lined with a smooth white enamel, as he finds that the enamel is partly composed of lead... On testing some distilled water after it had been boiled in one of the saucepans which had been some time in use, the water was found to contain lead; and on examining a piece of the enamel, lead in considerable quantity was detected. Such saucepans ought to be banished from the kitchen.

The People's Medical Journal, 1850

Pikul and Plante, Enameled Kitchenware: American and Europeanfrom Amazon.com or Amazon UK

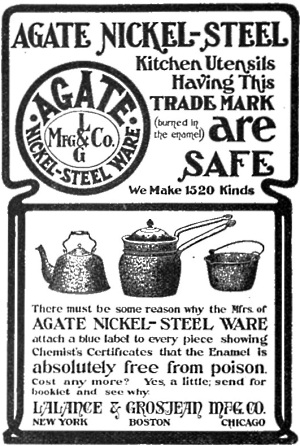

Any iron utensils, such as frying-pans, soup-kettles, saucepans, broilers, etc., that are kept in a basement, should be coated with grease before the family leaves town for a three months' absence in the summer. The task is not pleasant, but it is more agreeable than coming home to find such articles masses of rust. The precaution is not necessary if the agate iron-ware manufactured by Lalance & Grosjean is used. This never rusts, and is easily kept clean. The distinction should be made between this and the common granite-ware. The agate iron is free from the faults of chipping and scaling off that one sometimes observes in the ordinary granite ironware.

Housekeeping Made Easy, NY, 1888

Helen Greguire, Granite Warefrom Amazon.com or Amazon UK

Nancy Carlisle, America's Kitchensfrom Amazon.com

Encyclopedia of Kitchen History by Mary Snodgrass

from Amazon.com

or Amazon UK

History of enamelware - kitchen & household

Early enamel-lined cooking pots

Think about enamel

kitchen utensils today, and you probably imagine something coated all over in enamel.

That certainly wasn't the case in the early years. To begin with, cooking pots were

lined inside with enamel, but they looked like any other cast iron on the outside. People wanted a way of coating iron

to stop metallic tastes or rust getting into food: something acid-resistant and

easy to clean without laborious scouring,

something more durable than the tin linings used inside copper.

Think about enamel

kitchen utensils today, and you probably imagine something coated all over in enamel.

That certainly wasn't the case in the early years. To begin with, cooking pots were

lined inside with enamel, but they looked like any other cast iron on the outside. People wanted a way of coating iron

to stop metallic tastes or rust getting into food: something acid-resistant and

easy to clean without laborious scouring,

something more durable than the tin linings used inside copper.

The story of enamel cookware begins in the 1760s in Germany. The idea of finding a safe, convenient coating first took hold there: in scientific writing and in actual iron works. Fifty years later vitreous enamel linings, also called porcelain, for kitchen pans were becoming familiar in several European countries. Enamelling was no longer limited to decorative arts and crafts.

Were enamel-lined cooking

pots really as clean and safe as they seemed? Some people praised them as far better

than anything known before. Others spoke of poisonous ingredients leaching into

the food. Finding out what cooks or housekeepers thought in the early days is not

so easy.

Were enamel-lined cooking

pots really as clean and safe as they seemed? Some people praised them as far better

than anything known before. Others spoke of poisonous ingredients leaching into

the food. Finding out what cooks or housekeepers thought in the early days is not

so easy.

Over the next few decades enamel-coated metal came into use for domestic pots, pans, basins, as well as for street signs, medical equipment and more. And yet enamelware was still a long way from the attractive and useful mass-produced utensils of the late 1800s and early 1900s.

Enamel in the USA: flourishing after a late start

Enamelled

cookware came to the US after Western Europe. Around 1850 Americans began to own

enamel-lined culinary utensils, but they were very plain, nothing like the colourful

mottled surfaces that were yet to come. The Stuart & Peterson foundry in Philadelphia

was making enamel-lined cast iron pots in the 1860s.

Enamelled

cookware came to the US after Western Europe. Around 1850 Americans began to own

enamel-lined culinary utensils, but they were very plain, nothing like the colourful

mottled surfaces that were yet to come. The Stuart & Peterson foundry in Philadelphia

was making enamel-lined cast iron pots in the 1860s.

The interior of the hollow ware, as prepared by the steam lathe, is covered with a white paste, and put into the oven to be dried. After drying, it is transferred to an enamelling oven, where a white heat, sufficient to melt glass, is applied, which fuses this coating, making it soft as liquid glass. While in this state it is swiftly taken from the oven, rapidly covered with a white powder, and immediately returned back to the oven, where it is again subjected to a white heat, aud finally taken out to be gradually cooled in the open air. The enamel is, in fact, a regular coating of porcelain upon the metal, and with ordinary care is imperishable. On the contrary, the enamelled iron ware made in England (which has been nearly driven out of American consumption by Stuart & Peterson's manufacture) finally runs into an infinitesimal number of minute cracks, which chip off and render the vessel quite useless.

A history of American manufactures from 1608 to 1860, Bishop, Freedley, and Young, 1868

Plenty was written about unsatisfactory

cookware:

Plenty was written about unsatisfactory

cookware:

Ten years ago the porcelain-lined kettles were considered a great invention for boiling substances that required particular care, and many a thrifty housekeeper has congratulated herself on the possession of one, and then grieved herself sick almost to find it burned black in a few days, through the carelessness of servants, and just as liable to spoil her delicacies as an ordinary tin saucepan.

Lady's Home Magazine, Philadelphia, 1857

The utensils for roasting and even grinding coffee are now frequently lined with porcelain, as are many other articles for the kitchen. No doubt the porcelain is exceedingly clean and nice while it remains perfect; and it is an advantage to the coffee-berry especially not to be brought into immediate contact with heated metal. But porcelain-lined articles are not only very expensive, but they never can be depended on. They are quite as liable to crack and fly in pieces the first time of using as the fiftieth; and, of course, are of no further service.

The Art of Confectionery, Tilton and Co., Boston, 1865

It was in the 1870s that a surge of competitive creativity began to change American kitchenware. Out of this came the huge range of enamel goods spattered, speckled, and splashed, which appeal to collectors today. Two companies led the way in patenting and promoting innovations: not just attractive surface decoration but continuing improvements in enamelling sheet metal joints, attaching handles etc. We shouldn't forget that throughout the 1800s changes in metal working are important in the story of enamelware. It's not all about the surface.

Mottled, marbled, or plain?

The first two big US

companies making enamel homewares were founded by migrants from Europe in the 1860s.

One company had French heritage, the other German.

Lalance and Grosjean started as a business importing sheet metal and metal

homeware before setting up their Manufacturing Company in New York, with a metal

stamping factory in Woodhaven. Their mottled enamel was agateware, typically blue.

The first two big US

companies making enamel homewares were founded by migrants from Europe in the 1860s.

One company had French heritage, the other German.

Lalance and Grosjean started as a business importing sheet metal and metal

homeware before setting up their Manufacturing Company in New York, with a metal

stamping factory in Woodhaven. Their mottled enamel was agateware, typically blue.

Frederick and William Niedringhaus built up the St. Louis Stamping Co. in Missouri, then moved graniteware production to Granite City, Illinois. They later evolved into NESCO, whose grey enamel was sometimes said to flow from "pure melted granite" . They got the first US patent for a mottled enamel finish, just a few months before a competing patent by L & G. Both companies went on to patent numerous improvements: from better spouts to novel surface decoration.

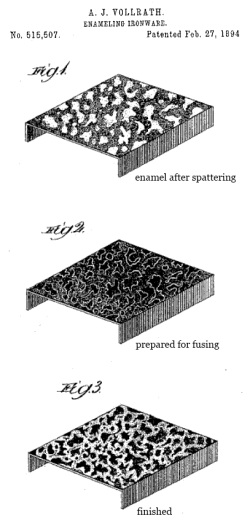

Vollrath managed to establish itself a little later, and there were

other companies too. Carl Vollrath had to assert the uniqueness of his enamelling

method to get a patent for his kind of "enameled iron-ware of the kind known

as speckled or pepperedware":

Vollrath managed to establish itself a little later, and there were

other companies too. Carl Vollrath had to assert the uniqueness of his enamelling

method to get a patent for his kind of "enameled iron-ware of the kind known

as speckled or pepperedware":

The ware is distinguished from what is known as mottled ware, such as granite or agate ware, in the fact that the contrasting specks are produced by the incorporation in the enamel coating of an agent which presents the contrasting color, whereas in the case of the mottled ware the specks or spots are not only generally of a larger and somewhat less defined character than those found in the speckledware, but are caused by the absorption into the glaze of oxide of iron formed upon the surface of the metal during the process of enameling.

From Vollrath's 1893 patent

The best-known brands, especially

the granite and agate ware names, held onto a strong position into the 20th century.

They sold for higher prices. In 1899 Lalance and Grosjean’s “Agate nickel-steel

ware” was much more expensive than Haberman’s “grey mottled enameled ware” L&G's

2 quart lipped saucepan cost 18¢ ; Haberman's was 7¢. Meanwhile, Sears had a

set of 17 pieces of "Peerless gray enamel ware" selling for about $2.70.

The best-known brands, especially

the granite and agate ware names, held onto a strong position into the 20th century.

They sold for higher prices. In 1899 Lalance and Grosjean’s “Agate nickel-steel

ware” was much more expensive than Haberman’s “grey mottled enameled ware” L&G's

2 quart lipped saucepan cost 18¢ ; Haberman's was 7¢. Meanwhile, Sears had a

set of 17 pieces of "Peerless gray enamel ware" selling for about $2.70.

Agate nickel-steel ware ads claimed a "chemist's certificate" proving it free of "arsenic, antimony, and lead" from the 1890s onward. Enamel had not quite shaken off the suspicion that some formulas leaked toxins into cooked food. Today most enamelled cast iron usually has a plain, often white, lining however gorgeously coloured the outside is.

At the time when mottled enamel was a huge success in the USA some countries stuck to a plainer look. Classic British enamel was typically white with navy trim, though deeper colours were also used. Sweden had a lot of cream with green edging. Other countries had a mixture of plain and speckled, with folk art decoration, like floral motifs, also popular in some places.

New rivals - aluminium, stainless steel, Pyrex, plastic - brought serious competition.

From the 1930s enamelled metal was never again an "obvious" attractive, affordable

choice.

New rivals - aluminium, stainless steel, Pyrex, plastic - brought serious competition.

From the 1930s enamelled metal was never again an "obvious" attractive, affordable

choice.

Timeline: enamelled metal for culinary and domestic use

- 1761 ~ J. H. G. von Justi suggested a way of enamelling copper in his collected chemical writings

- 1764 ~ A German manufacturer in Königsbronn was producing enamelled stoves and cookware lined with enamel

- 1779 ~ Learned society in Paris offered 900 livres prize for the invention of a new substance for kitchen utensils, minus the disadvantages of all the others

- 1781 ~ Sven Rinman in Stockholm described experiments in lining copper or hammered iron cooking pots with enamel, using 20 different "recipes". Said Justi's proposed method unworkable.

- 1799 ~ Dr. Samuel Sandy Hickling of Birmingham, Warwickshire, patented a way of coating iron with enamel. He understood both decorative and practical potential. A factory started production of "enamelled hollow wares" using his method but gave up for lack of "due encouragement".

- 1837 ~ J.J.A. Mourot of Louvain received a Belgian patent for an improved enamel for stoves. He claimed a high level of heat resistance that outdid the enamel used on casseroles.

- 1837 ~ Christoph Erde of Thuringia, published a book with instructions for enamelling iron cookware. (Gründliche Anweisung zum Emailliren und Verzinnen der gegossenen und geschlagenen eisernen Kochgeschirre)

- 1839 ~ Thomas and Charles Clark of Wolverhampton, Staffordshire, patented a way of "glazing and enamelling cast-iron, holloware, and other metallic substances". They were iron manufacturers, not gentleman scientists like Rinman and Hickling, and their company went on to produce and market enamelled metal items for cooking, hygiene etc. Later they sued Kenrick (see next item) for producing similar goods, but lost.

- 1851 ~ At the London Great Exhibition "cast-iron enamelled culinary vessels" were shown by Archibald Kenrick & Sons of West Bromwich, Staffordshire along with other enamelled things including a water-closet pan and a spittoon. Timothy Kenrick of the same town registered a patent in 1846 for "enamelling the surfaces of certain cast iron articles".

- 1852 ~ At a meeting of the Franklin Institute in Philadelphia, PA, a Dr. Kennedy showed members enamel vessels of stamped iron from France, and told how "the business of enamelling iron was fast assuming importance on the [European] continent". He said the "expense of enamelled culinary articles was but slight; he had bought [in Sèvres, near Paris], an iron saucepan of the capacity of a quart, and enamelled on both sides, for...24 cents..." Railroad and street signs, "breast-pins, plant-labels, tomb-tablets, and a host of other articles of beauty or utility, are cheaply supplied by the skill of the French enamellers."

- 1853 ~ The New York Exhibition showed "various tinned, turned, and enameled culinary and household articles" manufactured by "Cresson, William P., & Co., Philadelphia, Pennsylvania".

- 1876 ~ US patent for "enameling sheet-metal ware", "beautifully-mottled" and "more durable", granted to the Niedringhaus brothers

- 1877 ~ US patent for sheet metal containers made of overlapping sections and coated in enamel, assigned to Lalance and Grosjean, acknowledging the 1876 patent - quoted below

- 1889 ~ Carl Vollrath's first US patent - a way of producing a "mottled or pleasingly-speckled appearance"

- 1892 ~ enamelled steel became a cheaper alternative to enamelled iron around this date

- Early 1900s ~ legal disputes over enamelware patents in the USA continued, like this one

- 1930s ~ Enamel kitchenware losing prime position. New alternatives were just as good or better.

...We are aware that sheet-iron vessels constructed of a single piece of sheet metal have been stamped into shape and enameled in mottled colors to represent granite and marble, and also that sheet and cast metal vessels have also been enameled with vitreous enamels, when constructed in one piece, and this we do not wish to claim.

What we claim, and desire to secure by Letters Patent, is —

A sheet-metal vessel constructed in two or more sections, united at the edges by semicircular overlapping joints, and coated with vitreous enamel, whereby the lapped joints are cemented together and held, and the vessel strengthened and ornamented, substantially as set forth...

1877 patent for inventors John C. Milligan, of South Orange, New Jersey, and George Booth, of Philadelphia, Pennsylvania, assignors to Lalance and Grosjean

...until a few years ago, almost all thinly enameled ironware, whether of wrought or cast iron, had a plain surface or one of uniform color, blue, brown, violet, white or gray. Subsequently there was introduced and extensively sold upon the market so-called mottled ware, or granite or agate ware, which is ware in which the enamel coating is given a variegated appearance...

1894, Vollrath patent

Notes

~ To find out about specific patterns and finishes from a collector's point of view

you will probably need at least one serious collector's reference book, and/or membership

of a

collector's society.

~ Graniteware is a general name for speckled or mottled enamel nowadays, often used

without meaning the original brand.

5 March 2012

5 March 2012

You may like our new sister site Home Things Past where you'll find articles about antiques, vintage kitchen stuff, crafts, and other things to do with home life in the past. There's space for comments and discussion too. Please do take a look and add your thoughts. (Comments don't appear instantly.)

For sources please refer to the books page, and/or the excerpts quoted on the pages of this website, and note that many links lead to museum sites. Feel free to ask if you're looking for a specific reference - feedback is always welcome anyway. Unfortunately, it's not possible to help you with queries about prices or valuation.